CFD Research is a well-established, Huntsville-based small business founded in 1987. Since our founding, we have demonstrated exceptional technical performance, innovation, and transition of enabling technologies to our customers and the warfighter. Our innovative ideas, technologies, and approaches translate into value for customers and warfighters. We are comprised of an exceptional team of engineers, technicians, developers, and practitioners experienced in supporting mission objectives.

Significant Contributions to Military Technology

Throttleable Solid Rocket Motor Technology

CFD Research has continued to refine and demonstrate throttleable solid rocket motor technology applicable to Army tactical missile systems since 2002. Our team has demonstrated the significance of a high thrust turn-down capability to numerous existing and future Army tactical missile boost-sustain solid rocket motor configurations. Several prior CFD Research, Army, and support contractor studies, as well as limited flight demonstration efforts, have shown how missile range and lethality can be significantly enhanced using throttleable solid rocket motor propulsion.

CFD Research has demonstrated passive variable-area Solid Rocket Motor nozzle operability that possesses minimized complexity, weight, volume and cost. This technology offers compatibility with insensitive munition (IM) progressive propellants for implementation into Army tactical missile systems. The fundamental advantage this technology offers is variable thrust, at will, with extremely low electrical power consumption. This novel throttling method enables mission flexibility while minimizing the additional on-board power requirements (< 10 W).

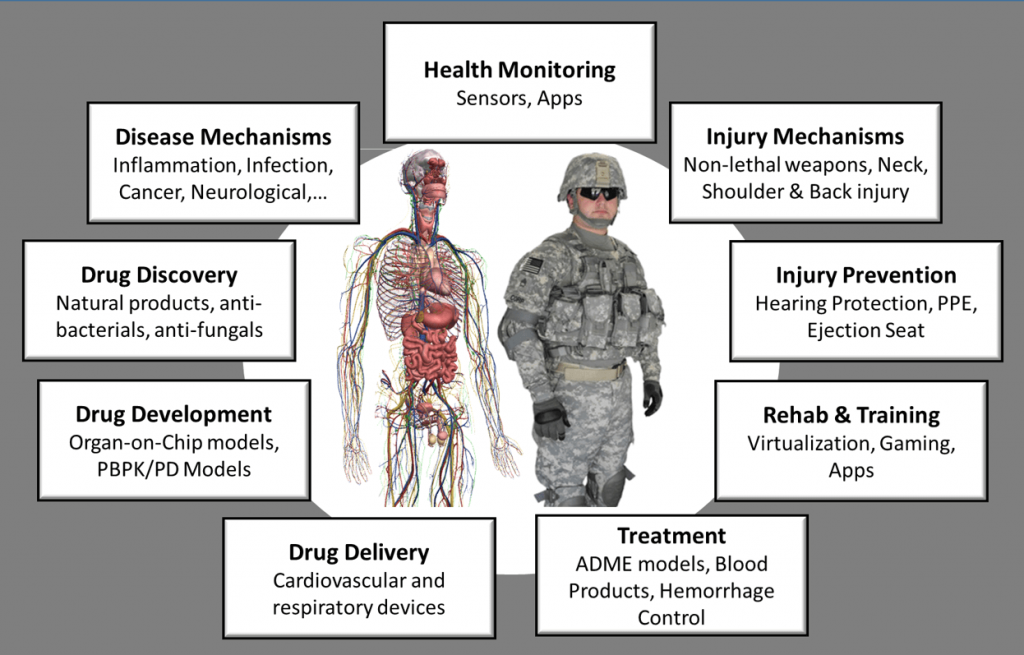

Soldier Protection

CFD Research has collaborated with DoD, prime contractors, and academic partners to advance soldier protection efforts for our nation’s warfighters. Using state of the art computational modeling along with developing novel test methods and devices and warfighter systems biological effects, we take a full multiscale and multisystem look at soldier protection.

For computational investigations into solider protection, we use CoBi to analyze loads from adverse events such as blast, ballistics, impacts, etc and translate those into physiological responses and injury/damage risks. We can evaluate personal protective equipment performance or dive deeper into the biological effects of these adverse events such as directed energy and chemical weapons.

Physical experiments are conducted in pursuit of creating new technologies and methods to protect the warfighter such as anatomical surrogates that provide human like responses to adverse events. We also develop devices and technologies aimed at better protecting the warfighter during a trauma event such as blood loss or TBI using state of the art organ on chip devices and portable blood separating equipment.

Thermal Battery Technology

CFD Research has been developing novel high capacity materials for thermal batteries since 2009. Thermal Batteries are unique in that they use a molten salt electrolyte, which is “frozen” at room temperature and thus allows a fully charged battery to have an extremely long shelf-life of 20+ years. When battery power is needed, the system is heated in a matter of milliseconds to melt the electrolyte into its “molten” state and thus allow the battery to start delivering power.

In the defense industry, thermal batteries are primarily used to power guidance and control systems on missiles. The range of existing missiles is currently limited by the capacity of existing thermal batteries. CFD Research has focused on development of higher voltage and higher capacity cathode and electrolyte materials. The increased energy density, or capacity allows for longer run-time and range for missile systems or a smaller and lighter battery footprint for the same capacity and range. Current technology has demonstrated 40% improvement in capacity over current state of the art. CFD Research has licensed this technology to a leading thermal battery manufacturer.

Hypersonic Mission Support

Hypersonic weapons systems are subject to aeroheating friction and atmospheric particulate encounters which can result in material loss on nosecones and control surfaces impacting flight stability performance. The speed requirements of modern systems are too extreme for ground testing to help fully understand the physics of these phenomena. CFD Research’s development and application of modeling and simulation tools for the aerothermodynamic and weather environment is therefore critical to extrapolating ground test procedures to the flight environment.

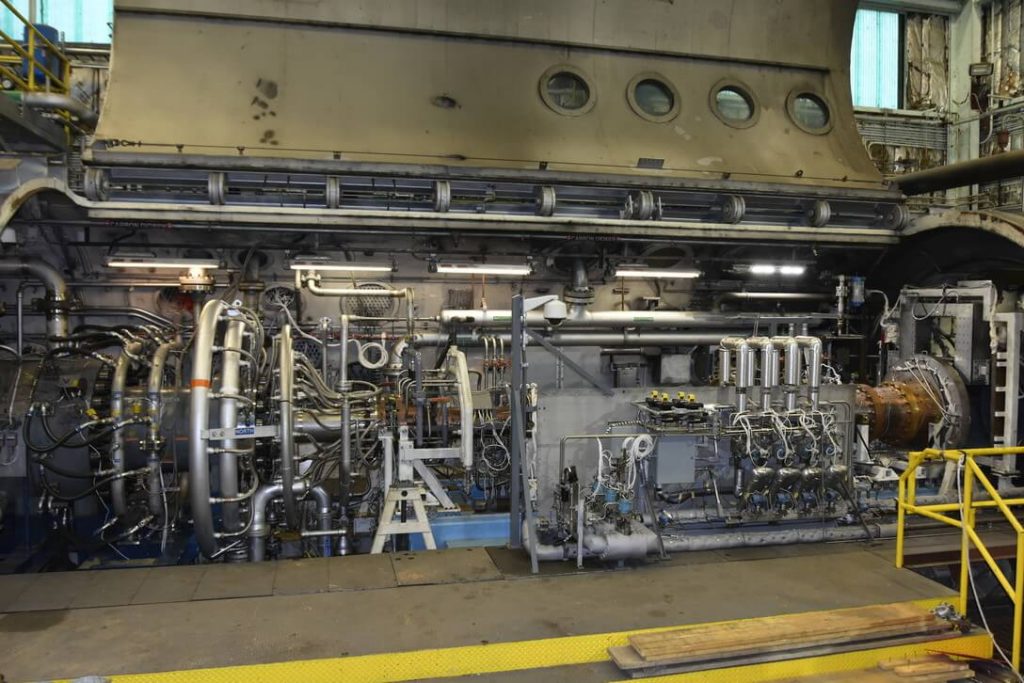

When a DoD evaluation of the nation’s test facilities concluded that improvements were needed to test at scale in a thermally-relevant environment, AEDC’s Aerodynamic and Propulsion Test Unit (APTU) facility at Arnold Air Force Base underwent a two-year upgrade. This upgrade enabled large-scale scramjet combustor tests and included technology developed by CFD Research under the Small Business Innovative Research program. Our technology proved crucial in achieving record setting test conditions.

Select Customers Served